A well-designed supply schedule ensures the seamless flow of goods, minimizes disruptions, and enhances overall productivity. In this comprehensive guide, we will delve into the intricacies of creating effective supply schedules, covering key concepts, best practices, and tools that can streamline the process.

Understanding Supply Schedules:

A supply schedule is a detailed plan that outlines the production, procurement, and distribution of goods over a specific period. It serves as a roadmap for businesses to manage their resources effectively and meet the demands of the market. The schedule considers factors such as demand forecasts, production capacities, lead times, and inventory levels to ensure a balanced and efficient supply chain.

Key Components of a Supply Schedule:

Demand Forecasting:

Accurate demand forecasting is the foundation of a successful supply schedule. Businesses must analyze historical data, market trends, and other relevant factors to predict future demand. Advanced forecasting techniques, such as predictive analytics and machine learning algorithms, can enhance accuracy and reliability.

Production Planning:

Once the demand is forecasted, businesses need to plan their production accordingly. Production planning involves determining the quantity of goods to be manufactured, scheduling production runs, and optimizing production processes. Factors like production capacity, machine availability, and labor resources play a crucial role in this phase.

Procurement Strategy:

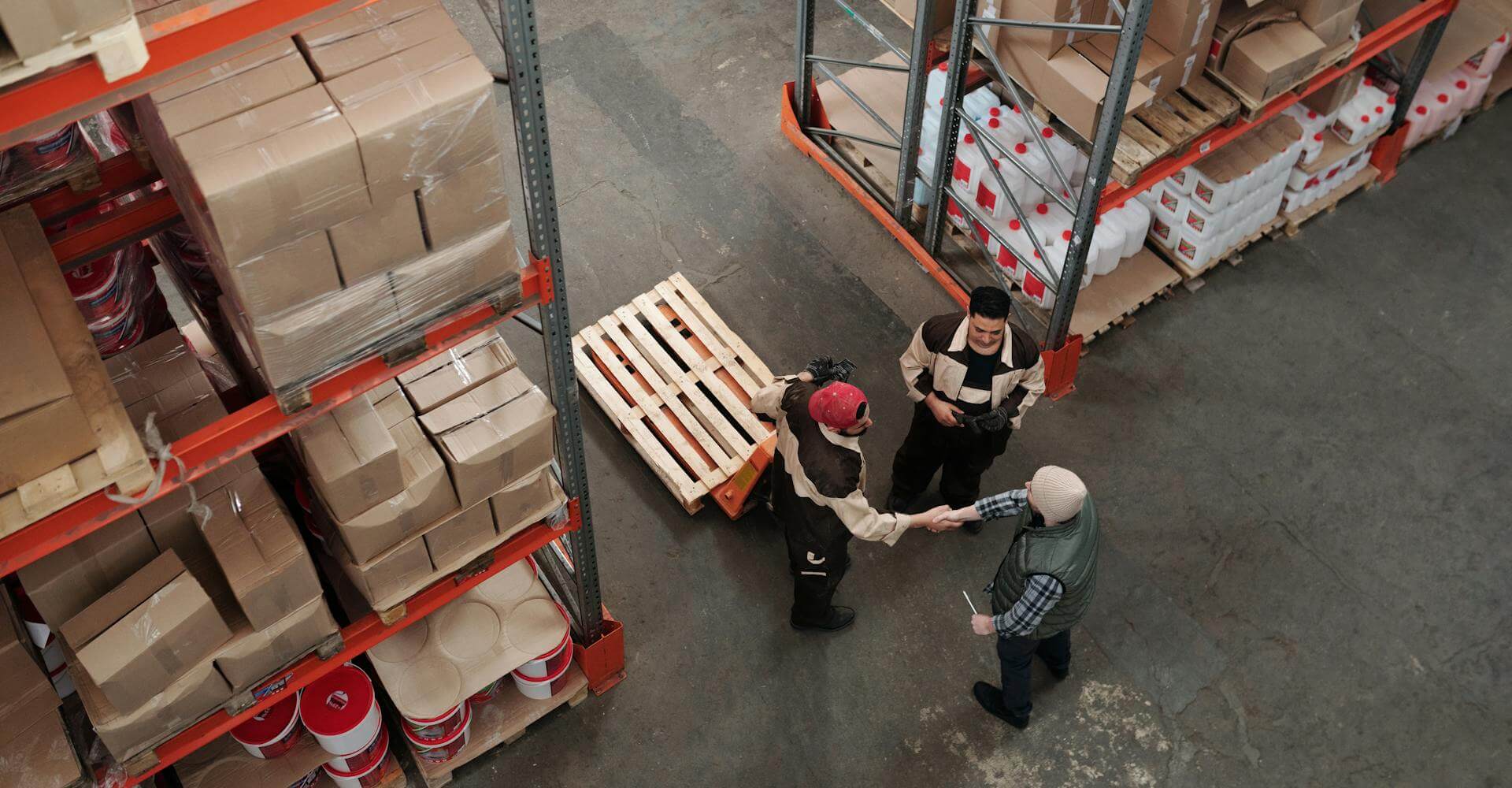

A well-thought-out procurement strategy ensures that raw materials and components are sourced efficiently. This includes selecting reliable suppliers, negotiating favorable terms, and maintaining strong vendor relationships. Businesses must consider factors like lead times, quality control, and cost-effectiveness when developing their procurement strategy.

Inventory Management:

Effective inventory management is essential for maintaining a balance between supply and demand. Businesses need to optimize their inventory levels to prevent stockouts or excess inventory. Just-in-time (JIT) inventory systems and safety stock calculations are common practices to achieve this balance.

Best Practices for Creating Supply Schedules:

Collaborative Planning:

Collaboration is key to successful supply scheduling. Involve key stakeholders, including production teams, procurement specialists, and sales representatives, in the planning process. This ensures that everyone’s inputs are considered, leading to a more comprehensive and realistic schedule.

Continuous Monitoring and Adjustment:

The business environment is dynamic, and unforeseen events can impact the supply chain. Regularly monitor the supply schedule and be prepared to make adjustments based on changes in demand, disruptions in the supply chain, or other unforeseen circumstances.

Utilize Technology:

Leverage advanced technologies and supply chain management software to streamline the scheduling process. Automation can help in data analysis, forecasting, and real-time tracking of inventory, leading to more accurate and efficient supply schedules.

Risk Mitigation:

Identify potential risks in the supply chain and develop contingency plans. Whether it’s a natural disaster, transportation issues, or supplier-related problems, having a proactive approach to risk management can prevent disruptions and keep the supply chain running smoothly.

Conclusion:

Creating effective supply schedules is a critical aspect of modern supply chain management. A well-crafted supply schedule is not just a plan; it’s a strategic tool that empowers businesses to thrive in a competitive market.